Intelligent compact drives

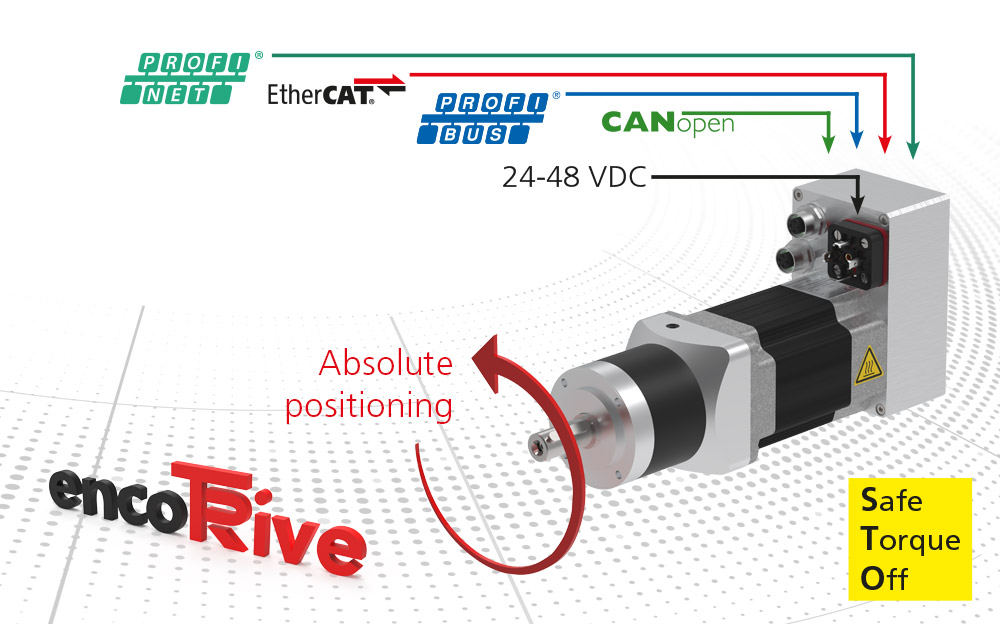

Voltage + fieldbus = positioning

Power supply and fieldbus connection – this is all that‘s required to implement actuating and positioning tasks in your system with encoTRive compact drives. The concept of gear motor with integrated positioning controller offers numerous advantages:

Advantages for the switch cabinet

- No space consumption and no heat emission by the drive electronics

Simple wiring

- No EMC-critical motor cables need to be laid

- Thanks to the extra-low voltage supply, all components and connections can be touched

Absolute position available at any time

- No reference runs required

- Reference initiators and associated wiring not necessary

Easy implementation of machine safety

STO (safe torque off) optionally integrated

Tailored to your application

- Broad range of motor and gear variants

- Wide power range from 50 to 400 watts

- Assistance with selection and design by our drive specialists

Advantages for the application software

- Control of different types identical within a fieldbus

- Changeover or mixed operation between PROFIBUS and PROFINET possible with minimum effort

- Example PLC projects available

Problem-free use overseas

- Optionally available as a UL-Recognized Component

Tailored to your specific application

The individual series are designed for application categories. This means that drives with the optimum scope of performance are available for automation tasks with a wide variety of requirements. The control is identical across all variants within the same fieldbus interface. This saves time and effort in the development of your application software.

Positioning drive

EC (brushless), for frequent and dynamic movements

Learn more

Actuating drive

DC (brush), for occasional movements

Learn more

Everything integrated

Interface

The encoTRive speaks many languages. It speaks the language of your control too.

Absolute encoder

Even if the drive is turned while de-energized, the absolute position is known as soon as the encoder is powered up again – battery-free, with a sturdy mechanical multiturn gear.

Positioning control

Simple to use:

Target and ramp parameters are preset using the fieldbus. Reliable positioning is handled entirely in the drive.

Power electronics

The necessary power commutation to move the drive quickly and powerfully into position is generated from the extra-low voltage supply.

Motor

Numerous motor sizes and variants are available to suit the wide range of applications. Whether brush motor or electronically commutated, with or without holding brake.

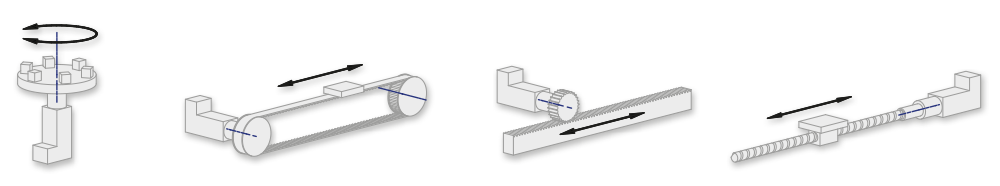

Gear

To consistently ensure the correct operating point, a wide range of gears with finely graduated reductions is available. Planetary gears - axial or with an angled stage - and worm gears are typical.

Safety

The safety functions STO (safe torque off) or SS1 (safe stop 1) are optionally integrated.