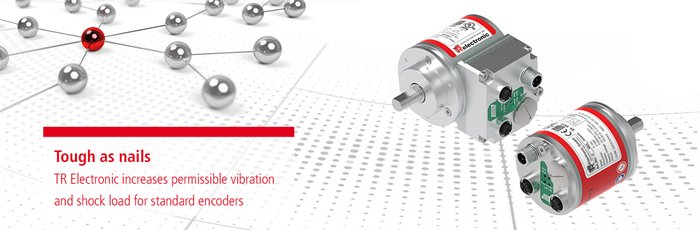

Tough as nails

TR Electronic increases permissible vibration and shock load for standard encoders

At TR Electronic, we love our encoders. That's why we naturally want to protect them from loads that would ultimately lead to failure or even destruction. And this is also very much in the interests of users who want to be able to rely on the function of standard and safety encoders from TR Electronic for many years.

Two important parameters for robustness are the permissible shock and vibration load. The corresponding tests are standardized so that values can be compared across manufacturers. If users adhere to these boundary conditions, they can assume that the encoder will reliably deliver the process-relevant measured values in the long term. Of course, the basic load can be reduced considerably with a good design. Some things can also be achieved through additional measures such as attachment bearings and couplings with damping elements. However, a rotary encoder that is already robust in itself makes it much easier to use.

New test procedures and equipment at TR Electronic have proven that TR's encoders are more robust than previously published. According to DIN EN 60068-2-27, the characteristic value for the permissible shock load for a CEV582 with PROFINET interface was 1000 m²/s (i.e. 100 times the acceleration due to gravity), previously with an exposure time of 11 ms for a half-sine shock. It has now been possible to tighten the specification for the duration of impact from 11 ms to 6 ms. A look at signal theory explains why the smaller number means a tightening of the condition. When testing a shock, an attempt is made to simulate the ideal shock (“Dirac impulse”). Of course, this is not possible in reality, but the shorter the exposure time, the steeper the edges of the real sine half-wave and thus also the force effect caused by this shock on the components in a rotary encoder. An albeit inadequate, but nevertheless helpful comparison could be: In the case of a punch, it is not only the force applied that is decisive. The faster the blow is delivered, the harder it is felt.

By testing the entire series with the new test systems, the permissible conditions for the 582 (solid shaft, blind hole shaft and hollow shaft), 802 (hollow shaft up to 25 mm) and 1102 (hollow shaft up to 50 mm) series devices have been tightened, giving users more freedom when selecting possible operating conditions.

C_582 Absolute rotary encoders – technical data

Press article including photograph