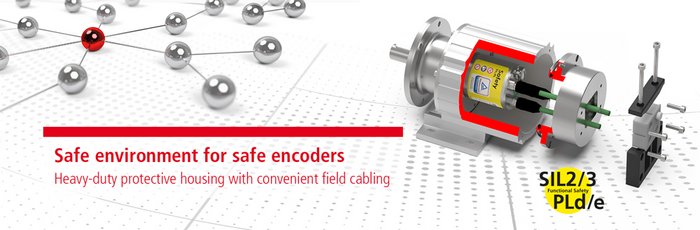

Safe environment for safe encoders

Heavy-duty protective housing with convenient field cabling

Particularly harsh environmental conditions have always been popular areas of application for rotary encoders from TR Electronic. Reinforced bearings and additional housing layers make the encoder almost impervious to external mechanical influences. At the same time, preassembled cables, especially with M12 connectors, are becoming increasingly popular. What is very practical and effective for normal environments can quickly lead to headaches in adverse conditions - an M12 connector is not particularly resistant to mechanical influences. Sometimes these different requirements come together: SIL encoders (CD_582+FS series from TR Electronic), increased forces on the shaft, risk of mechanical impacts on the housing and the desire to use preassembled cables. This requires a special solution.

With the new version of the protective housing with an outer diameter of 115 mm, TR Electronic has achieved precisely this feat.

The proven mechanics of the 115 protective housing offer a reinforced mounting flange and a robust mounting foot. Forces acting on the shaft are dissipated into the flange by two strong bearings. The internal rotary encoder is shielded from harmful influences by the surrounding continuous cast aluminum housing with a wall thickness of 20 mm.

Inside, there is space for an almost standard safety encoder from the CD_582 family. This series offers functional safety for applications that require SIL2 / PLd or SIL3 / PLe. The CD_582+FS series offers the following communication interfaces: PROFINET / PROFIsafe; Functional Safety over etherCAT; CIPsafety over Ethernet/IP, openSAFETY over Powerlink and CANopen safety. The shaft of the protective housing and the encoder are connected with the TR-specific claw coupling. This offers the precision of a solid shaft with the compact dimensions of a blind-hole shaft. In addition, the claw coupling is form-fit, which is an advantage for safety

applications and may even be necessary depending on the required safety level. A damping element protects the encoder from the last vibrations of the protective housing shaft. This connection is tried and tested at TR and was taken into account in the certification of the encoders.

The innovation in the new protective housing version lies in the connection bell. This can be opened completely by the user and thus provides direct access to the M12 connections of the encoder. Preassembled cables for incoming and outgoing bus and supply voltage are routed individually through the open sealing assembly. TR Electronic and ultimately the users rely on a proven brand product that offers suitable sealing adapters for various cable diameters. The cables are connected, the connection bell is screwed on and the seal assembly is mounted and clamped. The rotary encoder is thus fully protected.

Thanks to the use of pre-assembled cables, the connection does not require any special skills when connecting the usually very compact connectors in the field. The internally installed rotary encoder offers the tightness of a CDV582+FS even when the protective housing is open, so that the protective housing can also be opened for cabling in dusty environments.

Of course, the new protective housing is not only suitable for the safe encoders of the CD_582+FS series; all encoders of the 582 series (single scanning C__582, redundant CR_582) benefit from the new protective housing version - because pre-assembled cables are not only used in connection with functional safety and thus encoders are connected in harsh environmental conditions.

Press article including photograph